Airflow Measurement in Ducts

Measurement of air velocities in ducts can be done by using averaging airflow measurement probes. Sensors that are placed into ducts side and top as cross, allow calculating average air velocity entire section of the duct by connecting outlets parallel to each other. The sensor measures static and total pressure difference which gives dynamic pressure according to the principle of pitot. Pressure difference is measured by differential pressure transmitter and transmitted to PLC unit. Airflow can be calculated from the differential pressure which is transmitted to the PLC unit with the formula below.

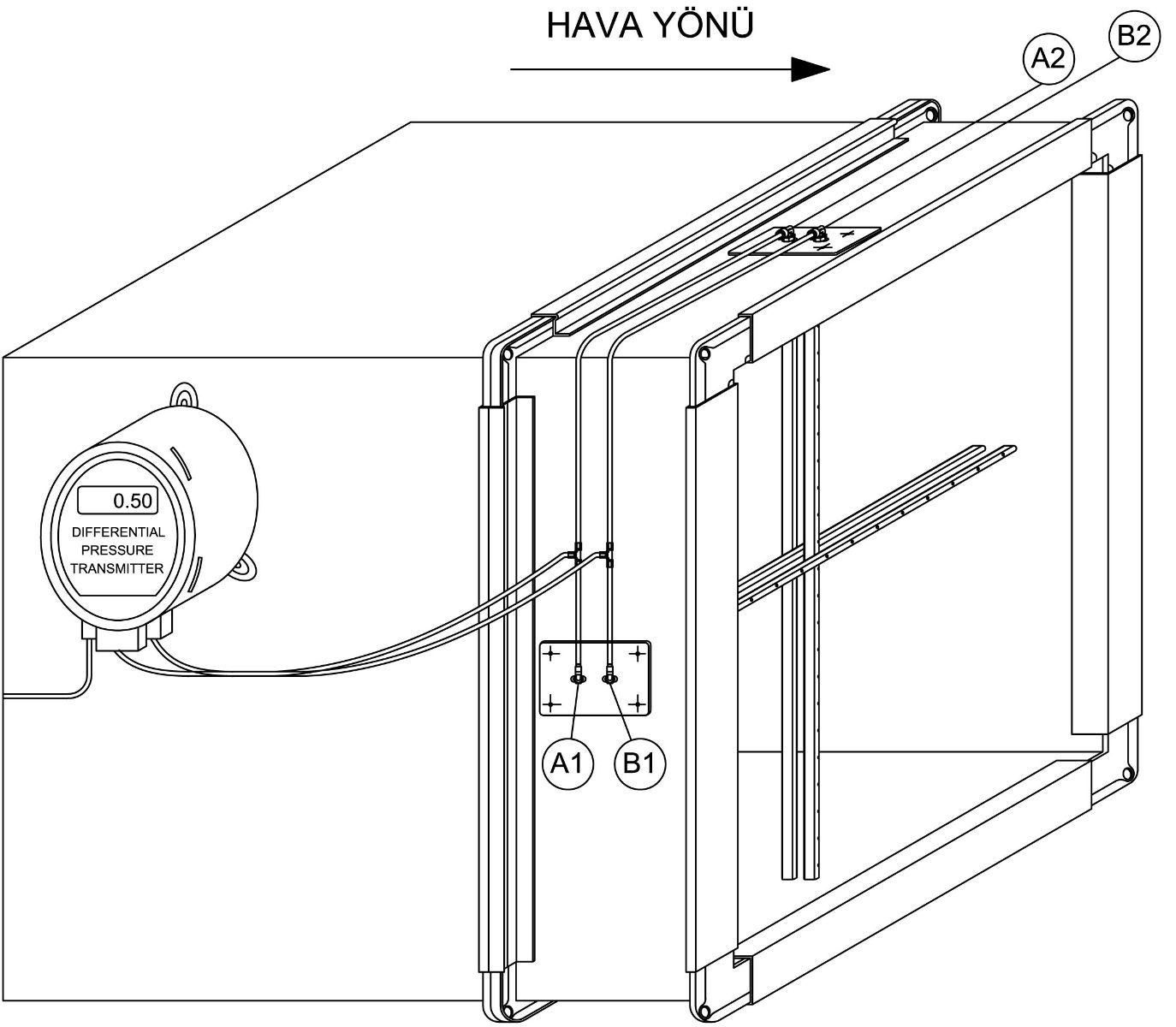

A1 and A2 terminals must be connected (+) pole of the differential pressure transmitter, B1 and B2 terminals must be connected to (-) pole in the same way. Electrical connection details of the differential pressure transmitter can be seen in prospectus of the unit.

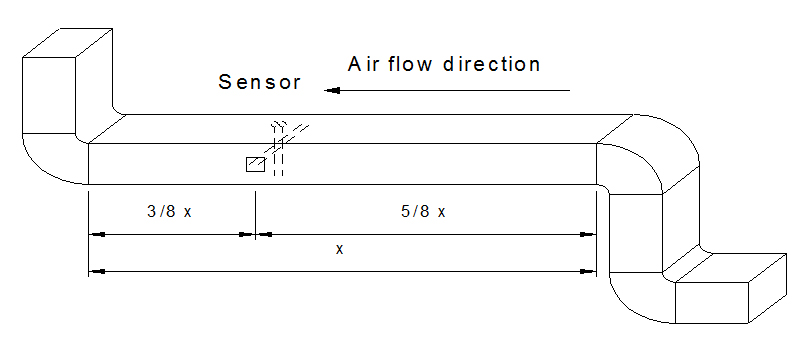

Important points at mechanical assembling of averaging airflow measurement probes in to air ducts;

- Probes have to mount at the longest flat point of the duct which will be at rat 5/8 before and 3/8 after the air flow direction.

- Probe flanges have to be parallel to duct sides. Otherwise measurement cannot be done well.

Example: If the longest flat point of duct is 4m, mounting space must be 5/8 so 2,5 m before and 3/8 so 1,5 m after the sensor.

Air Vel. m/s = 1,293 x (P)^1/2 (measured differential pressure) (Pa).........1

Airflow = Velocity x Duct section x 3600 ...................2

[m³/h] = [m/s] x [ m² ]